Kayan albarkatun kayan da aka haɗa sun haɗa da guduro, fiber da kayan mahimmanci, da dai sauransu.Akwai zaɓuɓɓuka da yawa, kuma kowane abu yana da ƙarfinsa na musamman, ƙanƙara, ƙaƙƙarfan ƙarfi da kwanciyar hankali na thermal, kuma farashinsa da fitarwa ma sun bambanta.

Duk da haka, kayan haɗin gwiwar gaba ɗaya, aikinsa na ƙarshe ba kawai yana da alaƙa da matrix resin da fibers (da kuma ainihin kayan aiki a cikin tsarin sanwici), amma kuma yana da alaƙa da tsarin ƙira da tsarin masana'antu na kayan a cikin tsarin. .

Wannan labarin zai gabatar da hanyoyin masana'anta da aka saba amfani da su, manyan abubuwan da ke tasiri ga kowace hanya da kuma yadda za a zaɓi albarkatun ƙasa don matakai daban-daban.

Bayanin hanyar:Tsarin gyare-gyaren da yankakken fiber ƙarfafa kayan da kuma tsarin resin ana fesa su a cikin ƙirar lokaci guda, sa'an nan kuma a warke a ƙarƙashin matsi na al'ada don samar da samfurin haɗe-haɗe na thermosetting.

zabin kayan aiki:

Resin: yafi polyester

Fiber: gilashin fiber yarn mara nauyi

Babban abu: Babu, yana buƙatar haɗawa da laminates daban

Babban fa'ida:

1) Sana'ar tana da dogon tarihi

2) Low cost, azumi fiber da guduro kwanciya

3) Low mold kudin

Babban rashin amfani:

1) Jirgin laminated yana da sauƙi don samar da yanki mai wadataccen resin, kuma nauyin yana da girma

2) Za a iya amfani da zaruruwa yankakken kawai, wanda ke da iyakacin ƙayyadaddun kayan aikin laminates

3) Domin sauƙaƙe spraying, resin danko yana buƙatar zama ƙasa da ƙasa don rasa injiniyoyi da kaddarorin thermal na kayan haɗin gwiwa.

4) Babban abun ciki na styrene a cikin guduro mai fesa yana nufin haɗarin haɗari ga masu aiki, kuma ƙarancin danko yana nufin cewa guduro yana da sauƙin shiga cikin kayan aikin ma'aikata kuma kai tsaye tuntuɓar fata.

5) Ƙaddamar da styrene mai canzawa a cikin iska yana da wuyar cika ka'idodin doka

aikace-aikace na yau da kullun:

Sauƙaƙan wasan zorro, ƙananan sassa na tsarin gini kamar jikin mota masu iya canzawa, wuraren baje kolin manyan motoci, wuraren wanka da ƙananan jiragen ruwa.

Bayanin hanyar:Cire zaruruwan da hannu da guduro.Ana iya ƙarfafa zaruruwan ta hanyar saƙa, ɗaki, ɗinki ko haɗawa.Akan yi kwanciya da hannu da rollers ko goge, sannan a matse resin da abin nadi na roba don ratsa zaruruwan.An warke laminates a ƙarƙashin matsa lamba na al'ada.

zabin kayan aiki:

Guduro: babu buƙata, epoxy, polyester, polyvinyl ester, guduro phenolic suna karɓa

Fiber: Babu buƙatu, amma fiber aramid tare da nauyin tushe mafi girma yana da wahala a shiga ta hanyar sa hannu.

Core material: babu bukata

Babban fa'ida:

1) Sana'ar tana da dogon tarihi

2) Sauƙin koyo

3) Idan an yi amfani da guduro mai zafin jiki na dakin, farashin mold yayi ƙasa

4) Babban zaɓi na kayan aiki da masu kaya

5) Babban abun ciki na fiber, zaruruwan da ake amfani da su sun fi tsayi fiye da tsarin feshi

Babban rashin amfani:

1) Haɗin resin, abun ciki na resin da ingancin laminates suna da alaƙa da ƙwarewar masu aiki, yana da wuya a sami laminates tare da ƙananan abun ciki na resin da ƙananan porosity.

2) Rashin lafiya da aminci na guduro.Ƙarƙashin nauyin ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar cuta ta hannun guduro, mafi girman barazanar lafiya.Ƙananan danko, mafi sauƙi shine guduro don shiga cikin tufafin aikin ma'aikata kuma kai tsaye tuntuɓi fata.

3) Idan ba a shigar da kayan aikin samun iska mai kyau ba, ƙaddamarwar styrene wanda aka canza daga polyester da polyvinyl ester zuwa cikin iska yana da wahala a cika ka'idodin doka.

4) Danko na resin sa-up na hannu yana buƙatar zama ƙasa sosai, don haka abun ciki na styrene ko sauran kaushi dole ne ya zama babba, don haka rasa kayan aikin injiniya / thermal na kayan haɗin gwiwar.

Aikace-aikace na yau da kullun:daidaitattun ruwan injin turbin iska, jiragen ruwa da aka samar da yawa, ƙirar gine-gine

Bayanin hanyar:Tsarin jakar jaka shine tsawo na tsarin shimfiɗa hannun da aka ambata a sama, wato, an rufe fim ɗin filastik a kan mold don share laminate da aka dage farawa da hannu, kuma ana amfani da matsin yanayi a kan laminate don cimma nasara. illar shaye-shaye da takurawa.Don haɓaka ingancin kayan haɗin gwiwa.

zabin kayan aiki:

Guduro: galibi epoxy da phenolic resin, polyester da polyvinyl ester ba su dace ba saboda suna ɗauke da sitirene, wanda ke jujjuyawa cikin famfo.

Fiber: Babu buƙatu, ko da zaruruwa tare da babban nauyi za a iya jika ƙarƙashin matsin lamba

Core material: babu bukata

Babban fa'ida:

1) Zai iya cimma mafi girma abun ciki na fiber fiye da daidaitaccen tsarin sa hannun hannu

2) The porosity ne m fiye da daidaitattun tsarin sa hannun hannu

3) A ƙarƙashin yanayin matsa lamba mara kyau, cikakken magudanar ruwa na resin yana inganta matakin wetting na fibers.Tabbas, wani ɓangare na resin zai zama abin amfani da injin

4) Lafiya da Aminci: Tsarin jakar jaka na iya rage sakin rashin ƙarfi yayin warkewa

Babban rashin amfani:

1) Ƙarin matakai suna ƙara farashin aiki da kayan jakar jakar da za a iya zubar da su

2) Babban buƙatun fasaha don masu aiki

3) Gudanar da hadawar guduro da abun ciki na guduro ya dogara ne akan ƙwarewar mai aiki

4) Ko da yake jakar injin ɗin yana rage sakin maras kyau, barazanar lafiyar mai aiki har yanzu tana da girma fiye da na jiko ko tsarin prepreg.

Aikace-aikace na yau da kullun:manya-manyan jiragen ruwa iyakantaccen bugu na lokaci guda, sassa na mota na tsere, haɗin ginshiƙan kayan gini a cikin jirgin ruwa

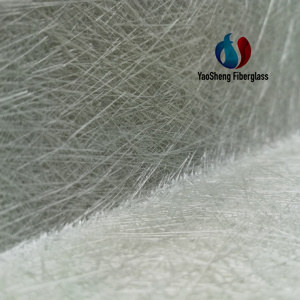

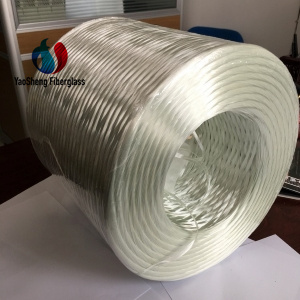

Deyang Yaosheng Composite Material Co., Ltd.ƙwararren kamfani ne wanda ke samar da samfuran fiber na gilashi daban-daban.Kamfanin yafi samar da Fiberglass roving, gilashin fiber yankakken madaidaicin tabarma, gilashin fiber zane / roving masana'anta / marine zane, da dai sauransu. Don Allah a ji free to tuntube mu.

Lambar waya: +86 15283895376

WhatsApp: +86 15283895376

Email: yaoshengfiberglass@gmail.com

Bayanin hanyar:Ana amfani da tsarin jujjuyawar ne don kera ɓarna, zagaye ko sassa na tsari kamar bututu da tankuna.Bayan dam ɗin fiber ɗin yana ciki da guduro, an yi masa rauni a kan mashin ɗin ta hanyoyi daban-daban, kuma injin ɗin yana sarrafa tsarin ta hanyar injin iska da kuma saurin injin.

zabin kayan aiki:

Guduro: babu bukata, kamar epoxy, polyester, polyvinyl ester da phenolic guduro, da dai sauransu.

Fiber: babu buƙatu, kai tsaye amfani da dam ɗin fiber na crel, babu buƙatar saƙa ko ɗinka a cikin zanen fiber.

Maɓalli mai mahimmanci: babu buƙatu, amma fata yawanci abu ne mai haɗaɗɗiyar Layer guda ɗaya

Babban fa'ida:

1) Saurin samarwa yana da sauri, kuma hanya ce ta tattalin arziki da ma'ana

2) Za a iya sarrafa abun ciki na resin ta hanyar auna yawan resin da ke ɗauke da fiber ɗin da ke wucewa ta cikin tankin guduro.

3) Rage farashin fiber, babu tsaka-tsakin tsarin saƙa

4) A tsarin yi yana da kyau kwarai, saboda linzamin fiber bundles za a iya dage farawa a daban-daban loading kwatance.

Babban rashin amfani:

1) Wannan tsari yana iyakance ga tsarin madauwari mara kyau

2) Zaɓuɓɓukan ba su da sauƙi a daidaita su daidai tare da jagorancin axial na bangaren

3) Farashin mandrel namiji mold ga manyan tsarin sassa ne in mun gwada da high

4) Tsarin waje na tsarin ba shine mold surface ba, don haka kayan ado ba su da kyau

5) Lokacin amfani da resin low-viscosity, ana buƙatar kulawa da aikin sinadarai da aikin lafiya da aminci.

Aikace-aikace na yau da kullun:tankunan ajiyar sinadarai da bututun isarwa, silinda, tankunan numfashi na kashe gobara

Bayanin hanyar:Ana tsoma ɗigon fiber ɗin da aka zana daga ramin ana tsoma shi ta cikin farantin dumama, kuma ana shigar da resin a cikin fiber ɗin da ke kan farantin dumama, kuma ana sarrafa abun da ke cikin resin, kuma a ƙarshe an warke kayan cikin siffar da ake buƙata;wannan samfurin da aka gyara mai siffa an yanke shi da injina zuwa tsayi daban-daban.Fibers kuma na iya shigar da farantin zafi a cikin kwatance fiye da digiri 0.

Pultrusion tsari ne mai ci gaba da samarwa, kuma sashin giciye na samfurin yawanci yana da tsayayyen siffa, yana ƙyale ƴan canje-canje.Gyara kayan rigar da ke wucewa ta cikin farantin zafi kuma yada shi a cikin tsari don warkewa nan da nan.Kodayake wannan tsari yana da mummunan ci gaba, zai iya canza siffar giciye.

zabin kayan aiki:

Guduro: yawanci epoxy, polyester, polyvinyl ester da phenolic guduro, da dai sauransu.

Fiber: babu bukata

Babban abu: ba a saba amfani da shi ba

Babban fa'ida:

1) Saurin samarwa yana da sauri, kuma hanya ce ta tattalin arziki da ma'ana don rigar rigar da magani kayan

2) Daidaitaccen sarrafa abun ciki na guduro

3) Rage farashin fiber, babu tsaka-tsakin tsarin saƙa

4) Kyakkyawan tsarin aiki, saboda ana tsara nau'ikan fiber a cikin madaidaiciyar layi kuma juzu'in ƙarar fiber yana da girma.

5) Za a iya rufe yankin shigar da fiber gaba ɗaya don rage sakin maras kyau

Babban rashin amfani:

1) Wannan tsari yana iyakance siffar giciye

2) Farashin farantin dumama yana da inganci

Aikace-aikace na yau da kullun:Gilashi da katako don tsarin gida, gadoji, tsani da shinge

6. Resin Transfer Molding (RTM)

Bayanin hanyar:Sanya busassun zaruruwa a cikin ƙananan ƙwayoyin cuta, sanya matsa lamba a gaba don sanya zaruruwan su dace da siffar ƙirar gwargwadon iyawa, kuma a haɗa su;sa'an nan, gyara na sama mold a kan ƙananan mold don samar da wani rami, sa'an nan kuma allurar da guduro a cikin mold rami.

Akan yi amfani da alluran da aka yi amfani da injin guduro da kuma shigar da zaruruwa, wato vacuum helped resin infusion process (VARI).Da zarar shigar fiber ɗin ya cika, an rufe bawul ɗin gabatarwar guduro kuma an warke abin da aka haɗa.Ana iya yin allurar guduro da warkewa a cikin ɗaki da zafin jiki ko kuma ƙarƙashin yanayi mai zafi.

zabin kayan aiki:

Guro: yawanci epoxy, polyester, polyvinyl ester da phenolic guduro, bismaleimide guduro za a iya amfani da a high zafin jiki.

Fiber: Babu bukata.Zaɓuɓɓukan da aka dinka sun fi dacewa da wannan tsari saboda raƙuman ƙwayar fiber ɗin suna sauƙaƙe canja wurin guduro;akwai filaye na musamman da aka haɓaka don sauƙaƙe kwararar guduro

Babban abu: Kumfa zumar zuma ba ta dace ba, saboda ƙwayoyin saƙar zuma za su cika da guduro, kuma matsa lamba zai sa kumfa ya rushe.

Babban fa'ida:

1) High fiber girma juzu'i da low porosity

2) Tunda an rufe resin gaba ɗaya, yana da lafiya da aminci, kuma yanayin aiki yana da tsabta da tsabta

3) Rage amfani da aiki

4) Na sama da ƙananan ɓangarorin ɓangaren tsarin su ne mold saman, wanda yake da sauƙi don jiyya na gaba.

Babban rashin amfani:

1) Tsarin da aka yi amfani da shi tare yana da tsada, kuma domin ya jure matsi mai girma, yana da nauyi kuma yana da wuyar gaske.

2) Iyakance ga kera kananan sassa

3) Wuraren da ba su da ruwa suna da wuya su bayyana, yana haifar da adadi mai yawa

Aikace-aikace na yau da kullun:kanana da hadaddun jirgin sama da sassa na mota, kujerun jirgin kasa

7. Sauran hanyoyin yin lalata - SCRIMP, RIFT, VARTM, da dai sauransu.

Siffar Hanya:Ajiye busassun zaruruwan kamar yadda tsarin RTM yake, sannan a shimfiɗa zanen sakin da ragamar magudanar ruwa.Bayan an gama shimfidawa, an rufe shi gaba ɗaya tare da jakar injin, kuma lokacin da injin ya kai ga wani buƙatu, ana shigar da resin a cikin dukkan tsarin shimfidawa.Ana samun rarraba resin a cikin laminate ta hanyar jagorantar guduro ta hanyar hanyar jagorar, kuma a ƙarshe busassun zaruruwa sun shiga gaba ɗaya daga sama zuwa ƙasa.

zabin kayan aiki:

Guduro: yawanci epoxy, polyester, polyvinyl ester guduro

Fiber: Duk wani fiber na kowa.Zaɓuɓɓukan da aka dinka sun fi dacewa da wannan tsari yayin da filayen dauren fiber ke hanzarta canja wurin guduro

Babban abu: kumfa saƙar zuma bai dace ba

Babban fa'ida:

1) Daidai da tsarin RTM, amma gefe ɗaya kawai shine mold surface

2) Daya gefen mold ne mai injin jakar, wanda sosai ceton farashin mold da kuma rage da ake bukata ga mold don jure matsa lamba.

3) Manyan sassa na tsarin kuma na iya samun babban juzu'i na ƙarar fiber da ƙarancin porosity

4) Za'a iya amfani da ƙirar ƙirar ƙirar hannun hannu don wannan tsari bayan gyare-gyare

5) Ana iya yin tsarin sanwici a lokaci ɗaya

Babban rashin amfani:

1) Don manyan sifofi, tsarin yana da rikitarwa, kuma ba za a iya kauce wa gyare-gyare ba

2) Danko na resin dole ne ya zama ƙasa da ƙasa, wanda kuma yana rage kayan aikin injiniya

3) Wuraren da ba su da ruwa suna da wuya su bayyana, yana haifar da adadi mai yawa

Aikace-aikace na yau da kullun:Gwajin kera kananan kwale-kwale, sassan jikin jiragen kasa da manyan motoci, injin injin injin iska

Bayanin hanyar:Fiber ko zanen fiber an riga an shigar da shi ta hanyar masana'anta na kayan aiki tare da guduro mai ɗauke da mai kara kuzari, kuma hanyar masana'anta shine babban zafin jiki da hanyar matsa lamba ko hanyar rushewar ƙarfi.Mai kara kuzari yana latent a yanayin zafin jiki, yana ba da kayan rayuwar rayuwa na makonni ko watanni a zafin jiki;firiji na iya tsawaita rayuwar sa.

Prepreg na iya zama hannu ko na'ura da aka ɗora a kan saman ƙirar, sa'an nan kuma an rufe shi a cikin jaka mai zafi kuma a yi zafi zuwa 120-180 ° C.Bayan dumama guduro na iya sake kwarara kuma a ƙarshe ya warke.Ana iya amfani da autoclave don amfani da ƙarin matsa lamba zuwa kayan, yawanci har zuwa yanayi 5.

zabin kayan aiki:

Guro: yawanci epoxy, polyester, phenolic guduro, babban zafin gudu guduro resistant kamar polyimide, cyanate ester da bismaleimide kuma za a iya amfani da

Fiber: Babu bukata.Za a iya amfani da bututun fiber ko zanen fiber

Mahimmin abu: babu buƙata, amma kumfa yana buƙatar zama mai juriya ga yawan zafin jiki da matsa lamba

Babban fa'ida:

1) Adadin guduro zuwa wakili na warkewa da abun ciki na guduro an saita su daidai ta mai siyarwa, yana da sauƙin samun laminates tare da babban abun ciki na fiber da ƙarancin porosity.

2) Kayan yana da kyawawan halaye na lafiya da aminci, kuma yanayin aiki yana da tsabta, mai yuwuwar ceton atomatik da farashin aiki.

3) An rage girman farashin filayen kayan aiki na unidirectional, kuma babu wani tsaka-tsaki da ake buƙata don saƙa zaruruwa cikin zane.

4) A masana'antu tsari na bukatar guduro tare da high danko da kuma mai kyau wettability, kazalika da inganta inji da thermal Properties.

5) Tsawaita lokacin aiki a cikin zafin jiki yana nufin cewa inganta tsarin tsari da tsarar sifofin hadaddun suma suna da sauƙin cimma.

6) Mai yuwuwar tanadi a cikin sarrafa kansa da farashin aiki

Babban rashin amfani:

1) Farashin kayan yana ƙaruwa, amma ba zai yuwu ba don biyan buƙatun aikace-aikacen

2) Ana buƙatar autoclave don kammala maganin, wanda ke da tsada mai yawa, tsawon lokacin aiki da ƙuntatawa girman

3) A mold bukatar yin tsayayya high tsari zafin jiki, da kuma core abu yana da guda bukatun

4) Don sassa masu kauri, ana buƙatar pre-vacuum lokacin da ake tanadin prepregs don kawar da kumfa na iska.

Aikace-aikace na yau da kullun:sassan tsarin jigilar sararin samaniya (kamar fuka-fuki da wutsiya), motocin tsere na F1

9. Prepreg - ba autoclave tsari

Bayanin hanyar:Ƙananan zafin jiki na curing prepreg masana'antu tsari daidai yake da autoclave prepreg, bambanci shine cewa sinadarai na guduro yana ba da damar warkewa a 60-120 ° C.

Don ƙananan zafin jiki na 60 ° C, lokacin aiki na kayan aiki shine mako guda kawai;don matsanancin zafin jiki (> 80 ° C), lokacin aiki na iya kaiwa watanni da yawa.Rashin ruwa na tsarin resin yana ba da damar warkewa ta amfani da jakunkuna kawai, guje wa amfani da autoclaves.

zabin kayan aiki:

Guduro: Yawanci guduro epoxy kawai

Fiber: babu bukata, daidai da prepreg na gargajiya

Kayan mahimmanci: babu buƙata, amma ya kamata a biya kulawa ta musamman lokacin amfani da kumfa mai mahimmanci na PVC

Babban fa'ida:

1) Yana da duk fa'idodin autoclave prepreg na gargajiya ((i.))-((vi.))

2) Kayan kayan kwalliya yana da arha, kamar itace, saboda zafin zafin jiki yana da ƙasa

3) Ana sauƙaƙe tsarin masana'antu na manyan sassa na tsarin, kawai buƙatar matsawa jakar injin, zazzage iska mai zafi na tanda ko tsarin dumama iska na ƙirar kanta don saduwa da buƙatun warkewa.

4) Hakanan ana iya amfani da kayan kumfa na yau da kullun, kuma tsarin ya fi girma

5) Idan aka kwatanta da autoclave, yawan amfani da makamashi ya ragu

6) Fasaha na ci gaba yana tabbatar da daidaito mai kyau da maimaitawa

Babban rashin amfani:

1) Farashin kayan har yanzu yana sama da busasshiyar fiber, kodayake farashin guduro ya yi ƙasa da prepreg aerospace

2) Mold yana buƙatar yin tsayayya da zafin jiki mafi girma fiye da tsarin jiko (80-140 ° C)

Aikace-aikace na yau da kullun:manyan jiragen ruwa na iska, manyan jiragen ruwa na tsere da jiragen ruwa, jirgin ceto, kayan aikin jirgin

10. Ba autoclave tsari na Semi-preg SPRINT/beam prepreg SparPreg

Bayanin hanyar:Yana da wahala a fitar da kumfa na iska tsakanin yadudduka ko jerawa yadudduka yayin aikin warkewa lokacin amfani da prepreg a cikin mafi kauri (> 3mm).Domin shawo kan wannan wahala, an gabatar da riga-kafi a cikin tsarin shimfidawa, amma an ƙaru sosai lokacin tsari.

A cikin 'yan shekarun nan, Gurit ya gabatar da jerin ingantattun samfuran prepreg tare da fasaha mai ƙima, yana ba da damar kera manyan laminates masu kauri (ƙananan porosity) don kammalawa a cikin tsari guda ɗaya.Semi-preg SPRINT ya ƙunshi yadudduka biyu na busassun fiber sandwiching wani Layer na tsarin sanwici na fim ɗin guduro.Bayan an ɗora kayan a cikin gyaggyarawa, injin famfo na iya zubar da iskar da ke cikinta gaba ɗaya kafin guduro ya yi zafi ya yi laushi kuma ya jiƙa zabar.m.

Beam prepreg SparPreg shine ingantaccen prepreg wanda, idan an warke a ƙarƙashin injin, zai iya cire kumfa mai sauƙi daga kayan da aka haɗe.

zabin kayan aiki:

Guduro: galibi resin epoxy, wasu resin kuma ana samunsu

Fiber: babu bukata

Mahimmin abu: mafi yawan, amma kulawa ta musamman ya kamata a biya ga yawan zafin jiki lokacin amfani da kumfa mai mahimmanci na PVC

Babban fa'ida:

1) Domin kauri sassa (100mm), high fiber girma juzu'i da low porosity har yanzu za a iya daidai samu.

2) Yanayin farko na tsarin resin yana da ƙarfi, kuma aikin yana da kyau bayan maganin zafin jiki mai girma

3) Bada izinin amfani da kyalle mai ƙarancin ƙima mai nauyi mai nauyi (kamar 1600 g/m2), haɓaka saurin kwance, da adana farashin masana'anta.

4) Tsarin yana ci gaba sosai, aikin yana da sauƙi kuma ana sarrafa abun ciki na resin daidai

Babban rashin amfani:

1) Farashin kayan har yanzu yana sama da busasshiyar fiber, kodayake farashin guduro ya yi ƙasa da prepreg aerospace

2) Mold yana buƙatar yin tsayayya da zafin jiki mafi girma fiye da tsarin jiko (80-140 ° C)

Aikace-aikace na yau da kullun:manyan jiragen ruwa na iska, manyan jiragen ruwa na tsere da jiragen ruwa, jirgin sama na ceto

Lokacin aikawa: Dec-13-2022